COFFEE MACHINE

Our coffee processing line saves time and boosts productivity, delivering clean, uniform, and high-quality coffee — perfectly ready for the market. With a streamlined process that includes impurity removal, weight grading, size grading, drying with a charcoal furnace, polishing, roasting, mixing, grinding, precise weighing, and final packaging.

HOPPER SCALE

Hopper scale MHS is used to weigh material of grain, such as paddy, corn, bean, etc. Ideal for the intake section of milling lines, it uses advanced load-cell technology for reliable results. The user-friendly control panel can be easily connected to a computer for efficient data management.

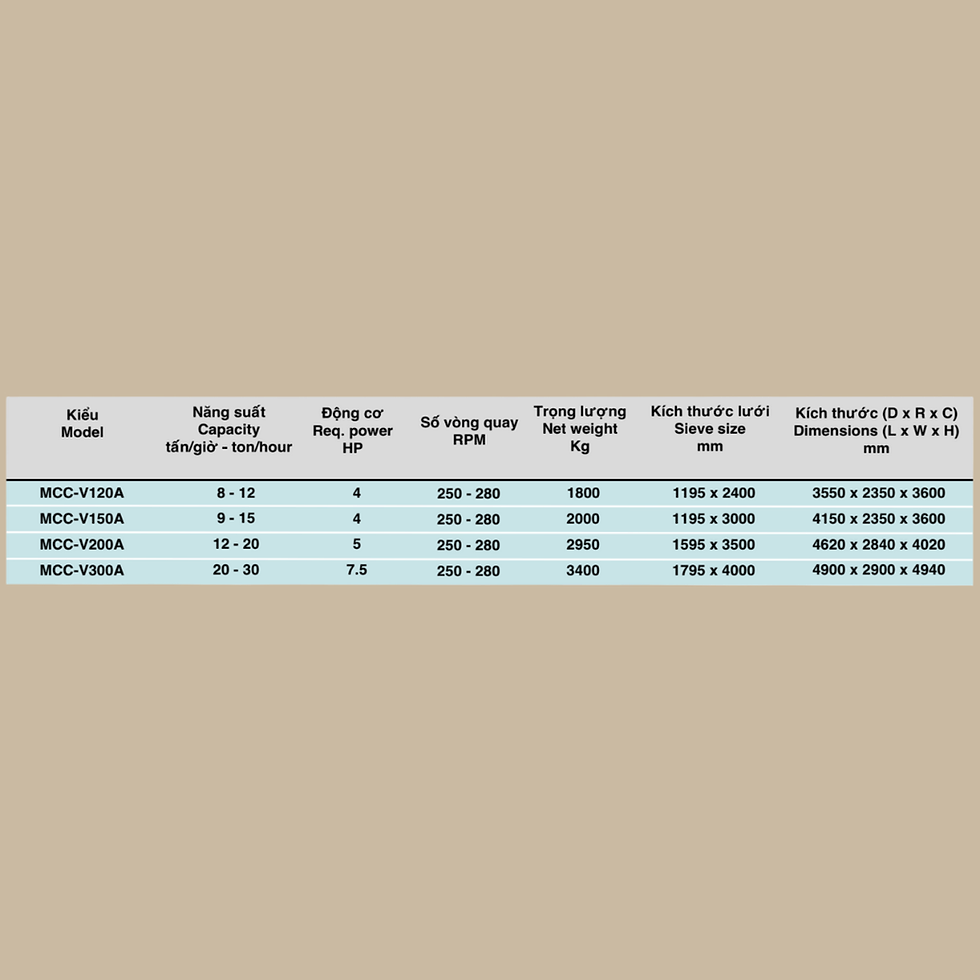

COFFEE PRE-CLEANER

Coffee Pre-cleaner MCC uses multiple screens to remove foreign materials such as husks, dried coffee cherries, wood pieces, stones, strings, sand, and other impurities.

The machine is designed with three layers of inclined screens that oscillate lengthwise, ensuring effective separation and high cleaning efficiency.

VIBRATING DESTONER

Vibrating Destoner Machine MVD is designed based on the density difference between stones, grit, and coffee beans.

The machine uses a slanted flanged screen that moves back and forth, combined with an exhaust-air current from the exhauster and cyclone, to effectively separate stones and grit mixed in coffee.

GRAVITY SEPARATOR

Gravity Separator MGS is designed to grade grains based on their weight differences.

The machine features an inclined oscillating screen that moves widthwise, enabling continuous and efficient separation.

A blower delivers compressed airflow from beneath, allowing the grains to float and stratify according to their individual weights.

This process ensures high-precision separation, producing clean and uniform grain quality.

GRAIN GRADER

Grain Grader MGG is designed to separate grains by size using multiple screen layers.

The number of screen layers can be configured to meet different capacity requirements.

Each layer is set at an incline and oscillates lengthwise, ensuring smooth operation and accurate grain grading.

GRAIN DRYER

Tower-shaped Dryer MGD is specifically designed for drying agricultural products. The system features horizontally parallel, inverted V-shaped channels for distributing hot air and discharging humid air, ensuring that hot air passes through the material and effectively removes the available water in the grain. The humid air is directed through dust filters before being released, ensuring that the exhaust air is clean and environmentally friendly. The system’s heat source can be supplied indirectly from a husk furnace, charcoal burner, oil burner, or a boiler with a radiator.

COFFEE POLISHING MACHINE

Coffee Polishing Machine MCP is designed to clean and enhance the shine of coffee beans by using a roller-and-screen system combined with controlled water spraying.

The machine features an automatic water spray system: water is sprayed only after the coffee enters the chamber (based on the preset timer) and automatically stops when no material remains inside.

It is also equipped with an automatic air cylinder for emergency situations or when the machine runs out of material.

The result is polished coffee with a high-gloss appearance, low breakage rate, and improved overall quality.

COFFEE ROASTING MACHINE

Coffee Roasting Machine MCR is used for roasting coffee beans and is constructed from stainless steel and heat-resistant steel to meet food-safety standards.

Roasting heat is uniformly distributed inside a rotating drum equipped with agitation wings, allowing consistent roasting quality and precise control of bean development.

The machine is fitted with a fast-cooling system and a stone-separation device. Liquefied Petroleum Gas (LPG) is used as the fuel source.

The machine is supplied with a smoke-treatment unit to minimize emissions and improve environmental performance.

COFFEE MIXING MACHINE

The coffee mixing machine MCM is used for mixing material in granules or powders, and is constructed from stainless steel to meet food-safety standards. It features a drum equipped with 2 screw conveyors rotating in different directions.

This machine allows the operator to precisely set up mixing duration and discharging time for optimal production efficiency.

COFFEE GRINDING MACHINE

Coffee Grinding Machine MCG operates using two corrugated rollers rotating in opposite directions at different speeds, allowing precise and controlled grinding.

A vibratory feeder delivers a uniform, single-layer flow of coffee beans directly into the roller gap, ensuring consistent feeding and stable grinding performance.

The rollers are cooled during operation to help preserve the coffee’s natural aroma. An upstream magnetic separator is included to remove metallic contaminants before grinding.

The final product achieves a uniform particle size. The machine can perform one-, two-, or three-stage grinding depending on the required fineness level.

SHUTTER SCALE

Shutter Scale MSS is used for weighing granular materials such as paddy, rice, coffee, corn, beans, etc and similar products, as well as powder materials such as rice bran. It is typically applied in the packing section of a production line. The scale operates on the load-cell principle, and its control panel can be connected to a computer for monitoring.

After weighing, the material is discharged directly into packaging bags positioned on the conveyor and sewing machine system. The conveyor height can be adjusted to accommodate different bag sizes.

-

MSS: for rice

-

MSS-H: for paddy, coffee, etc.

-

MSS-S: for rice bran